OEM´s Tier 2 and Tier 3

Process Capabilities

SHEET METAL PROCESS

Finn-Power Turret Press Punch 33Ton Capacity, Plus 7 Vertical Feeders For Raw Material, Amada Turret punch press 30ton capacity, 2 Cincinnati Press Brake 90 Tons, Trumpf Laser 2000 watt 5×10, Acupress press brake 60 tons, 2 Amada Laser 4,000 watt 5×10.

SECONDARY OPERATIONS FOR STAMPING

Rolling, Tamping, Spot Welding, Tumbling / Deburr, Finishing (outsourcing), Washer Machine, Assembly.

STAMPING

40, 110, 250, 500 Tons Capacity.

MOLDING

Haitian 80 Tons Molding Machine.

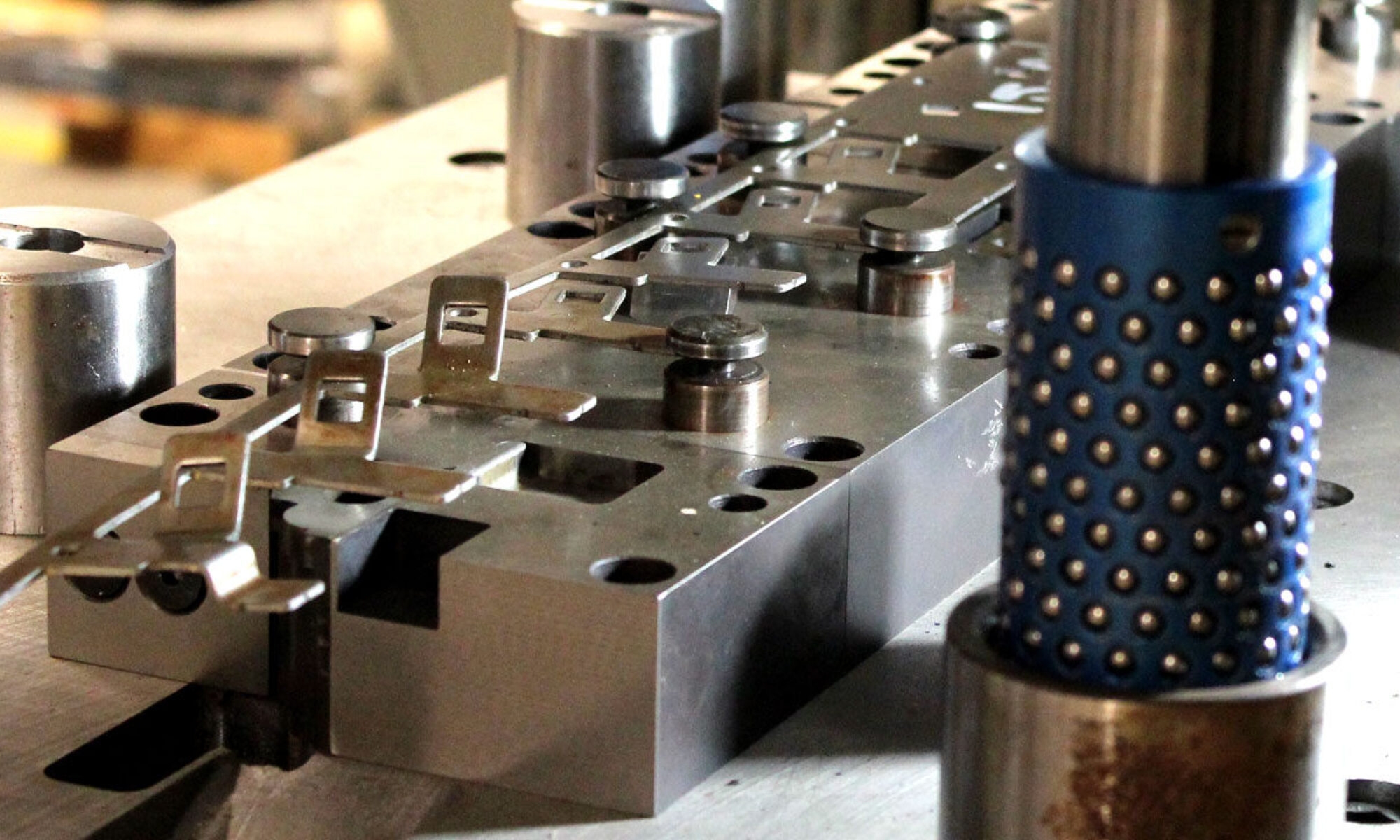

TOOL & DESIGN & BUILD-UP

In-House Die Design & Manufacturing.

PAINT

Paint Booths, Manual / Automatic.

Convection Ovens, UV Oven.

Pad Printing Machines.

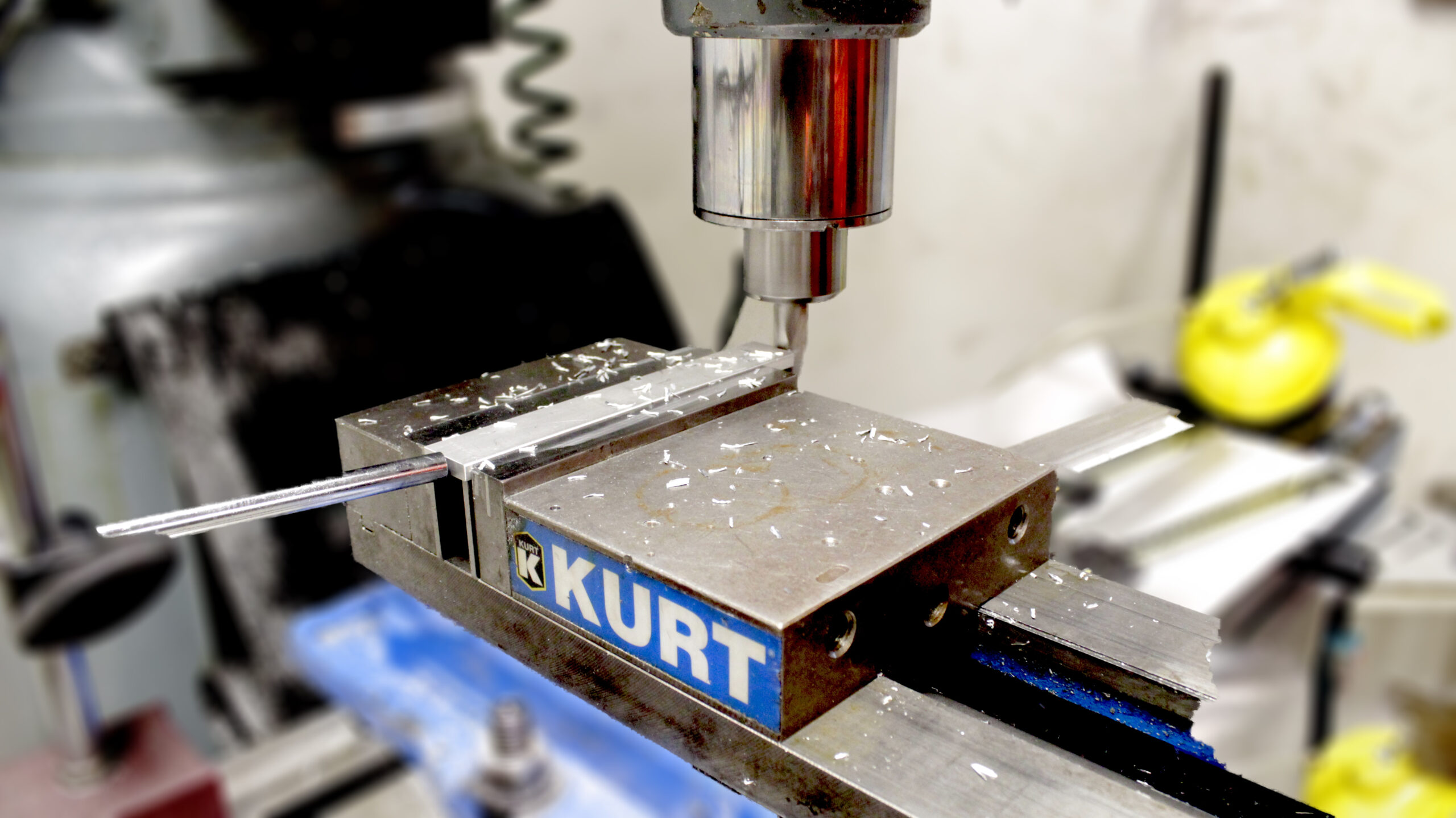

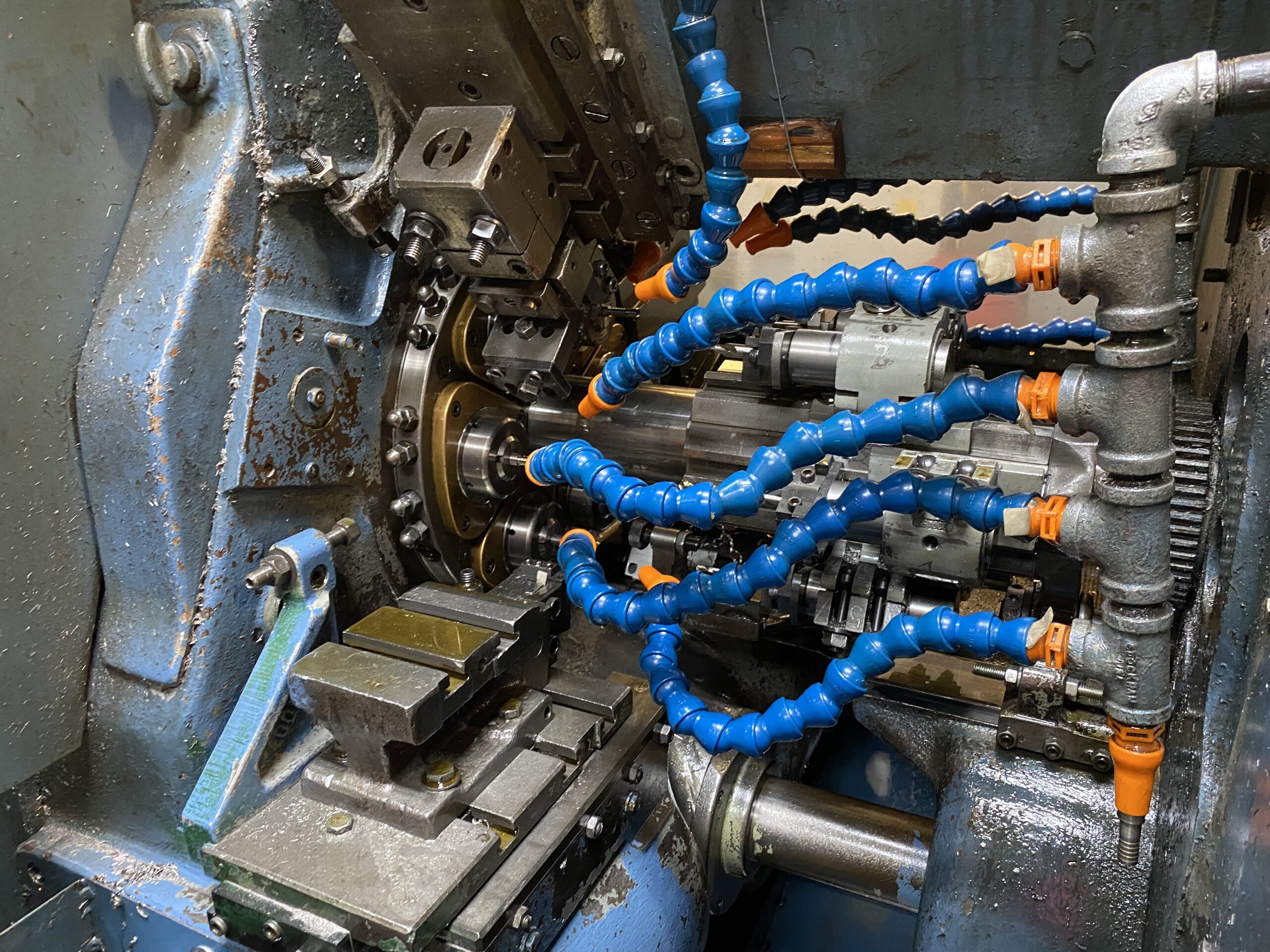

MACHINING

Turning, Milling, Boring, Slotting, Drilling & Tapping.

Screw Machine.

TESTING / QUALITY ASSURANCE

CMM, Micrometer / Caliper, Microscope, Spectro Meter, Glossmeter, ESD Measures Equipment’s.

SHIPPING (CUSTOMER REQUIRED SYSTEMS)

Final Inspection, Packaging, Labeling & Bar Coding, Own Freight (Daily Delivery).